08 May 2025

To further strengthen our employees’ quality consciousness and technical competencies, WOJIN Corporation recently conducted an innovative and immersive product quality training program. This comprehensive session, held at our state-of-the-art training facility, carried the impactful theme of "Continuous Improvement, Quality First" - a philosophy that lies at the heart of our manufacturing ethos. The carefully designed training curriculum was specifically developed to achieve multiple objectives: to deepen employees' understanding of quality benchmarks, to help them thoroughly master advanced product identification techniques, and to foster a sustainable culture of excellence in quality management.

During the comprehensive training session, the head of our Quality Management Department delivered a detailed and structured presentation that thoroughly explained all the essential technical parameters and precise process standards governing the company's core product lines. With special focus on manufacturing excellence, particular emphasis was placed on stringent quality requirements for critical components, including dimensional tolerances and surface finish criteria. To reinforce these concepts, our senior technical experts then conducted interactive live demonstrations that clearly illustrated the complete standard product inspection procedures. By utilizing actual physical samples from production, they provided employees with hands-on opportunities to develop a clear visual understanding of the exact characteristics - such as precise measurements, flawless finishes and optimal functionality - that distinguish truly high-quality products that meet our exacting corporate standards.

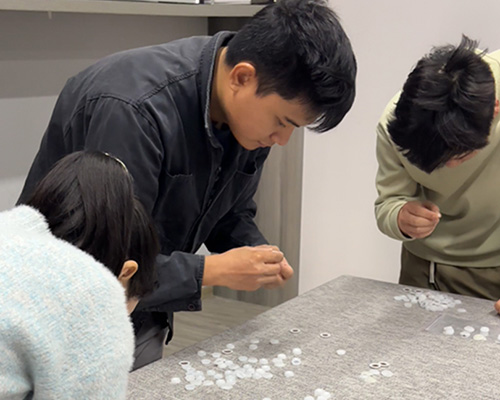

In the most practical session, the quality inspection department meticulously prepared mixed samples of qualified and defective exhaust valves, which were distributed to each people for physical identification. Employees were required to apply their newly acquired knowledge to accurately identify non-conforming products. This training approach that combines theory with practice significantly stimulated employees’ learning engagement.The highlight of the training came during the most practical hands - on session, where the quality inspection team had carefully prepared an extensive assortment of mixed samples containing both fully qualified and intentionally defective exhaust valve units. Under the guidance of quality supervisors, employees were challenged to methodically apply their newly acquired theoretical knowledge to accurately distinguish and document non-conforming products according to established quality criteria.

Excellence is born from attention to detail, and perfection begins with dedication. To produce outstanding products, one must first commit every detail to memory. Only through persistent pursuit of flawless quality can we earn customer trust in today's competitive marketplace.

This training program has not only enhanced employees' professional competencies but, more importantly, strengthened organization-wide quality accountability. It has established a solid foundation for the company's ongoing commitment to manufacturing premium products.

Tag: wojin

Originally published 08 May 2025, updated 08 May 2025.

Blog

Packaging That Needs a One-Way Degassing Valve

29 Jan 2026One way degassing valves release trapped gas, block outside air, suit gas-producing sealed products and prevent package swelling or bursting to preserve quality.

ISO and BRC System Audits Conducted in December 2025

30 Dec 2025In December, WOJIN completed ISO and BRC audits, reviewing production, quality control, process and identifying areas for continuous improvement.

WOJIN 13th Anniversary Team Building Journey

25 Nov 2025To celebrate WOJIN 13th anniversary, we proudly held a two-day team building activity that effectively strengthened teamwork and brought new energy.